STEPS IN DPF REMANUFACTURE PROCEDURE

What will a clogged DPF do?

Here is a short list of issues that most people complain about with a clogged DPF

Fault Codes / Limp Home Modes Triggered

Constant Regeneration processes

There are some other lesser known issues too like:

Increased Fuel Consumption

Decreased Power

Decreased Turbo life due to back pressure build up.

Cleaning or Remanufacturing?

The industry has really gone to three levels of cleaning:

1. Pneumatic / ‘Blow’

2. Bake and Blow

3. Remanufacturing.

It is obvious that the cleaner your filter is when going back on the vehicle means it will last longer in that particular service. And it’s not just the cost of the cleaning itself that needs to be considered. Also think about all of the on-costs. Labor to remove and refit, parts such as Gaskets and clamps. But that you also have added costs like increased fuel consumption etc.

So what goes into a DPF CLEANING Remanufactured DPF?

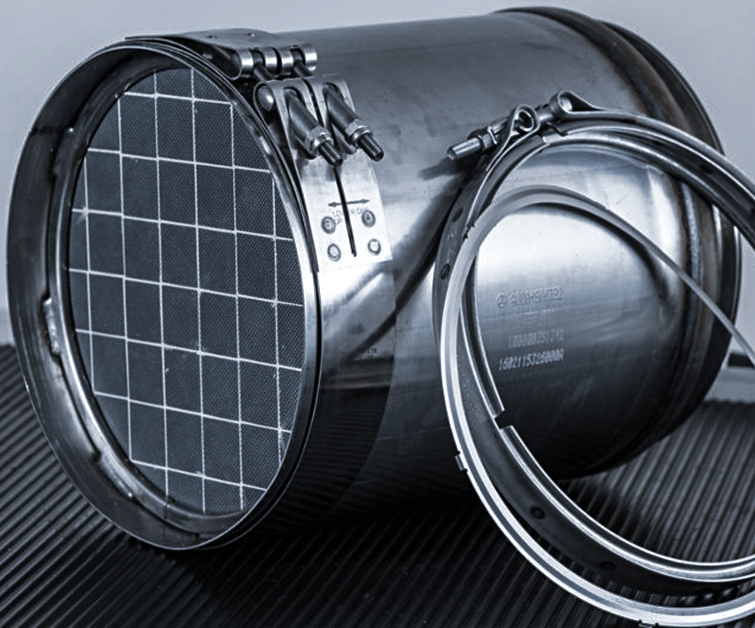

Step 1 - Testing and Validation

Our first step is a thorough examination of the dirty filter to ascertain its current performance and condition. The filter is checked for all its sealing services, cracks around sensor bungs, Filter flow and weight as well as cracked cores. If it passes these tests, then it can progress through to cleaning.

Step 2 - Basic Cleaning

Before any of the serious fun can begin, we need to start with the smaller details. Things like Sealing surfaces need to be cleaned and free of debris, we then complete a thorough cleaning of the exterior of the filter as well. Sensor bungs are thoroughly cleaned and retapped to ensure no little surprises are present when the filter goes back together.

Step 3 - Pneumatic Cleaning

Our first process is to thoroughly clean the filter out using high pressure compressed air in our industry leading Evacu-blast machine. This allows us to clean a lot of the material out before progressing to the later stages. By doing so, we actually improve the effectiveness of the

following steps.

Step 4 - Aqueous Cleaning

This is where some magic really happens. We use a very exclusive FFSolutions FH3 cleaning machine that is super effective at not only removing any remaining shoot, but also impacted ash from the DPF core. This is very important as its usually this impacted Ash that shortens a DPFs service life even if regular ‘cleaning’ is completed.

Step 5 - ‘Bake’ Thermal cleaning

It sounds somewhat similar to what you do on the truck, because, and with some important changes, that’s because it is similar to what you would already do on the truck.

What are these changes?

- Well our cycles are done for 12-20 hours depending on the filters, materials and various other factors.

- We’re completing these cycles when the vast majority of the material is already removed. This allows us to ‘free up’ the last of the remaining impacted ash that the Aqueous cleaning left behind.

Step 6 - Pneumatic again

Back around we go! We go back through this step because only our Evacu-blast machine has a special camera in the bottom of the machine that gives our highly skilled technicians the ability to see what material is still coming from the filter (if there is any). Sometimes we see some of the now free’d up ash left over from step 5 come out in the process. Having the ability to physically see what is happening via the camera is a major advantage in knowing when a filter is finally clean.

Step 7 - Re-Validation

Here is where you might start to see all the small little attention to detail things that we call our ‘DCARB Difference’. They’re at every stage of our processes and ingrained into our identity, but nowhere as obvious as here.

Our reporting process and validation process is lengthy, and more so, stringent. Not only that, but we provide full evidence for ultimate accountability that our product does what it says on the tin.

*Click here for a full video and article for what documentation comes with our Remanufactured filter services.