UNDERSTANDING HOW A DPF SYSTEM WORKS

Still don’t know what a clean and high-quality diesel particulate filter can do to your vehicle?

Check out our definitive guide on DPF system and how it works.

Understanding How a DPF System Works

Understanding how a diesel particulate filter works is essential when owning a diesel vehicle. More than knowing how to get your vehicles running, it’s important that you also know how to take good care of it when a problem arises.

That simply means you have to start understanding how a DPF system works. Today, we are going to talk on everything about DPF and how can you understand what signals your DPF is giving you.

What is a Diesel Particulate Filter (DPF)?

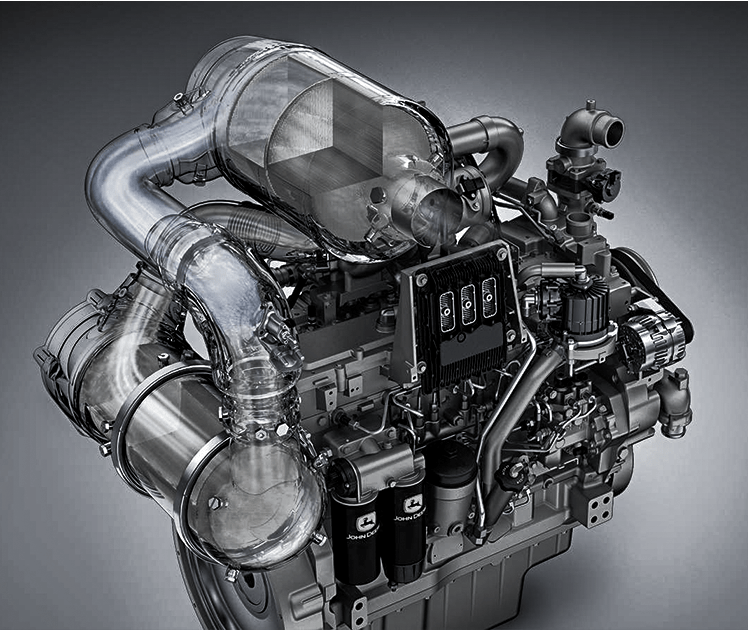

The term DPF stands for Diesel Particulate Filter. It is used in the diesel engine that is Euro-6 emission compliant. The manufacturers use the Diesel Particulate Filter to filter, store, and burn the soot particles which are emitted as a result of the combustion process of the diesel.

A diesel particulate filter (DPF) can remove virtually all the soot particulates (PM) from the exhaust gas emitted from a diesel engine to ensure compliance with very strict emission standards. Regardless of the actual emission limit, diesel particulate filters satisfy the needs of operators who place importance on achieving extremely low soot emissions.

Diesel Particulate Filters Mean Less Soot

The emission regulations for diesel engines are becoming stricter worldwide, which makes adjustments and developments to the drive systems necessary.

As a basic principle, DCARB’s approach to achieving compliance is to reduce emission levels by means of internal engine enhancements. Depending on the particular emission limits, it may be possible to do without a diesel particulate filter altogether. However, there is a relationship between the production of soot particulates and nitrogen oxides when internal engine measures are used if fewer soot particulates are produced during the combustion process, the quantity of nitrogen oxides increases, and vice versa.

In situations where emission requirements are strict with following standards, therefore, adding a diesel particulate filter is necessary, since it removes 90 percent or more of the soot particulates from the exhaust.This just simply means less soot and a safer vehicle for you and the environment.

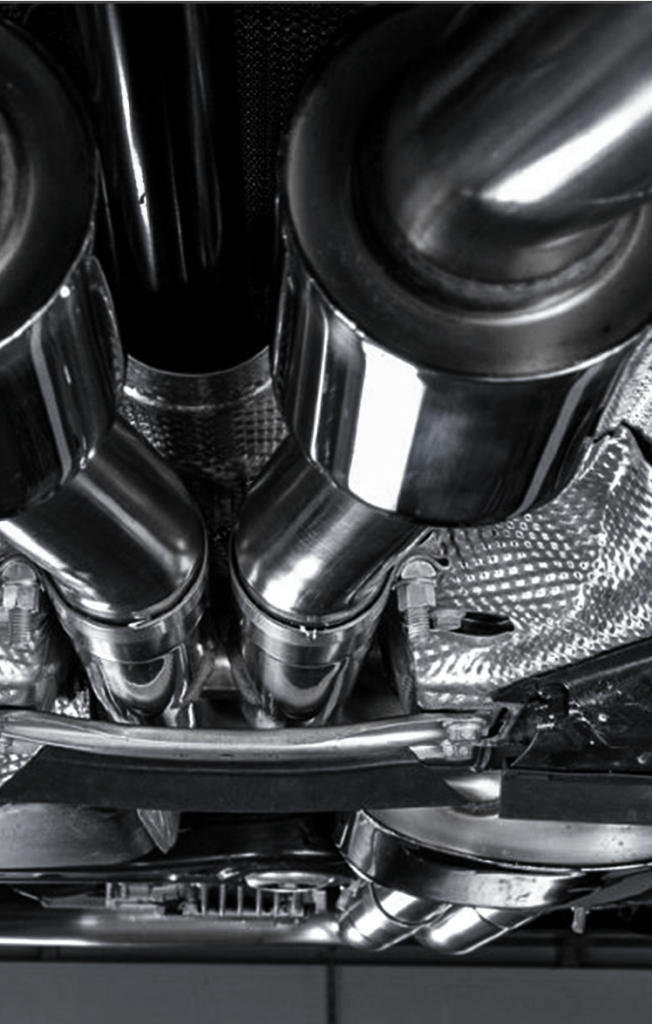

The Diesel Particulate Filter System: What Happens Down There?

The Diesel Particulate Filter (DPF) is a ceramic filter that has thousands of tiny channels or honeycomb-shaped openings that trap the soot onto the channel walls and prevent the particulate matter from exiting out the tailpipe. The honeycombed inner structure is covered with a layer of a chemical catalyst that contains small amounts of precious metals, usually platinum or palladium.

Diesel cars and trucks manufactured after 2009 must have a DPF, and in some cases, a Selective Catalysts Reduction (SCR) system. These components work together to reduce, and when working properly, remove all of the harmful NOx and soot from the exhaust. Not only does this help the environment, but it also creates a much cleaner engine.

Engine oil doesn’t get as dirty as fast as it would have without all of these systems in working order. Less soot mixed with the engine oil means less of that gritty carbon forming in the oil galleys and other moving parts. This increases the life of the engine at the same time it cleans the air.

The drawback to all of this is that the DPF needs to be cleaned regularly. The soot particles attach themselves to the lining of the DPF while the engine is running. At the same time, the filter is slowly clogging with the very particulates that it’s designed to remove from the exhaust.

This process of cleaning the DPF is done through a process called regeneration. There are several different methods used by various manufacturers to clean the DPF.

Passive Regeneration

Passive self-regeneration is completely transparent to the operator and does not affect the machine’s operation or performance.

The only indication when a passive regeneration cycle has been activated is either an exhaust temperature warning light indicating the exhaust temperature is higher than normal or a message stating a regeneration cycle is in process, or both.

Active Regeneration

Active self-regeneration occurs when there is not sufficient heat in the exhaust to convert the PM being collected in the DPF. The active regeneration is self-activated by the PCM based on various inputs.

The PCM sends a command to raise the exhaust temperatures by adding a small amount of injected raw fuel upstream of the DPF. The chemical reaction of the precious metals in the DPF and the raised exhaust gas temperatures oxidizes the PM from the filter.

Filter Failures

Some diesel exhaust filter failures are a result of not allowing the regeneration to take place. This will inadvertently clog the DPF to the point that replacement is the only option. Although it can be cleaned to some degree, a portion of functionality is still lost due to the severity of the restriction.

Another problem is when it is in regeneration and the excess heat combined with the clog causes the metal casing of the DPF to expand and rupture. Which, of course, means the only solution is to replace the DPF. The DPF requires professional cleaning every 150,000–250,000 miles or 5000 hours.